TXW13 Transfer Case

Project Overview

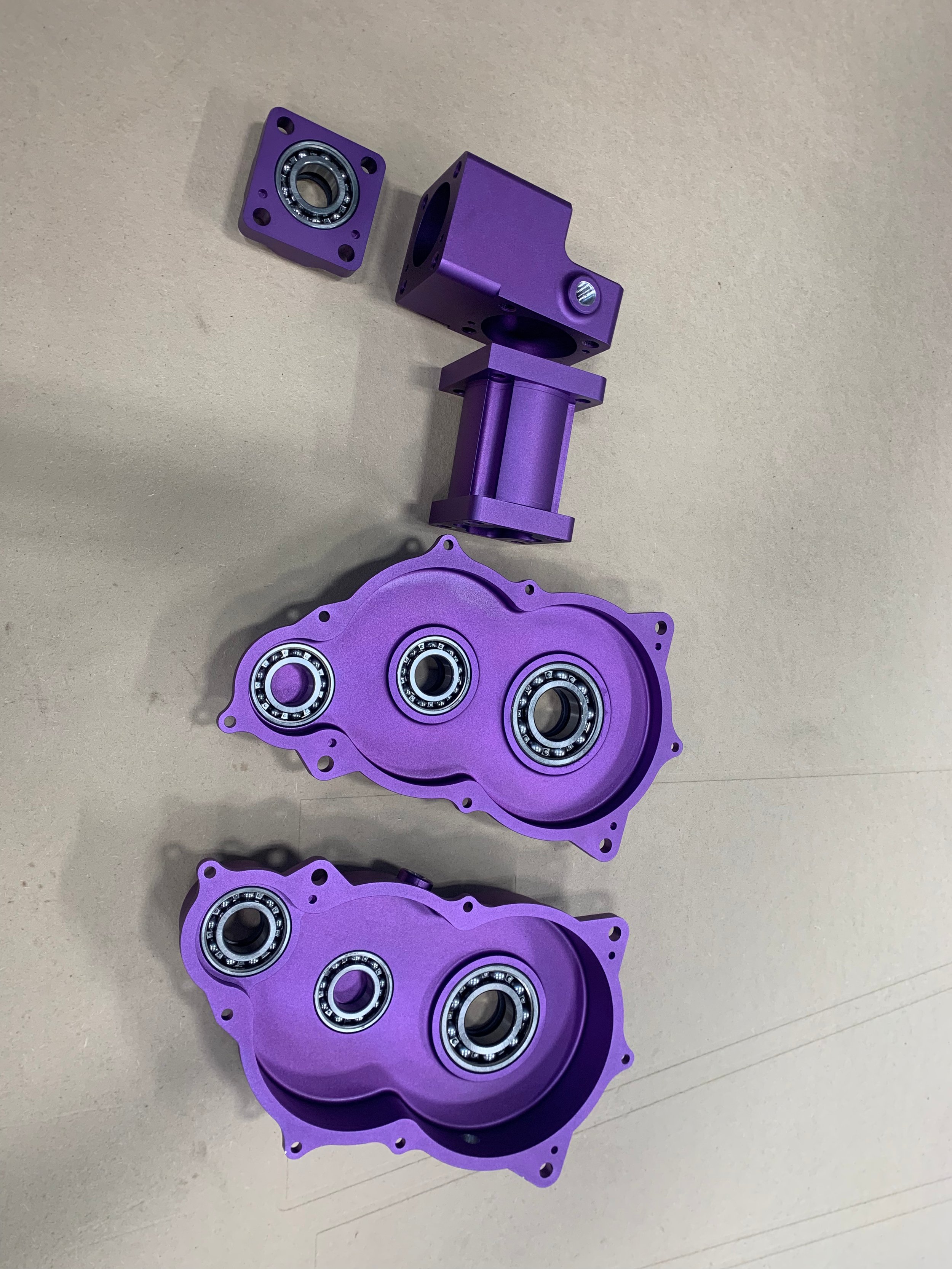

As drivetrain lead, I designed and developed a fully custom transfer case for Olivet Nazarene University’s TXW13 Baja SAE vehicle. Its architecture is based on a two-stage spur gear reduction, and a pair of bevel gears machined from 4041 steel, with a 6061-T6 aluminum case. The design optimally splits torque from the engine to all four CV axles while minimizing weight, size, and potential failure points.

My primary goal was to keep the system lightweight, serviceable, and robust under off-road load conditions. In order to achieve this, I used a spur gear train that utilized an internal oil-bath sealed enclosure. The transfer stage of the system utilizes a pair of bevel gears that optimize power output to the front differential. Furthermore, the case is split into 2 separate oil chambers, which allows for maintenance of either the main spur gears or just the bevel gears.

Design Features

Custom Internals

At the core of the transfer case lies the custom gear train, designed specifically to meet the vehicle’s performance goals. A series of spur gears, manufactured with module 2 geometry, a 20° pressure angle, and 15 mm face width, provide the main reduction while maintaining a compact profile. These gears were chosen not only for their efficiency but also for their ability to transmit torque smoothly while withstanding the repeated shock loads of off-road driving.

A custom bevel gear set was integrated into the layout to redirect torque from the rear of the vehicle to the front differential. By designing these spur and bevel gears in-house, the system achieves both the exact ratio requirements and the durability required for the competition.

To validate the durability of all internal components, Finite Element Analysis (FEA) was conducted SolidWorks and Creo Parametric on the spur gears, bevel gears, and shafts. This analysis confirmed that the gear teeth and shafts could safely endure peak torque levels with a factor of safety of 3, accounting for both bending stresses and surface contact fatigue. Furthermore, the geartrain was modeled as a whole to assess shaft deflection and housing stiffness, ensuring precise alignment under load. By combining robust hardware with validated structural performance, the transfer case is designed to provide reliable and consistent output in the most demanding racing conditions.

All gears and shafts excluding bevel gears.

Final Drive gear FEA validation.

Casing

The casing of the transfer case was designed with equal importance to the internal geartrain, as it provides the structural integrity and protection required for competition use. Machined from 6061-T6 aluminum, the housing possesses a balance between lightweight construction and the necessary stiffness to prevent deflection under heavy loading. It was split along a vertical plane to allow quick access for assembly, inspection, or servicing during competition. Reinforcing ribs were incorporated into the design to add rigidity without significantly increasing weight, while precisely machined bearing bores ensured accurate shaft alignment. O-ring grooves, fill and drain ports, and a breather vent were included to provide proper lubrication management and sealing against dust, mud, and water. This design approach ensured that the casing not only supported the gears and shafts but also contributed directly to the overall reliability and serviceability of the drivetrain.